CS 30 Notes on Using Matrix Operations

to Model the Flow of Materials in a Refinery

Mart Molle, April 2011

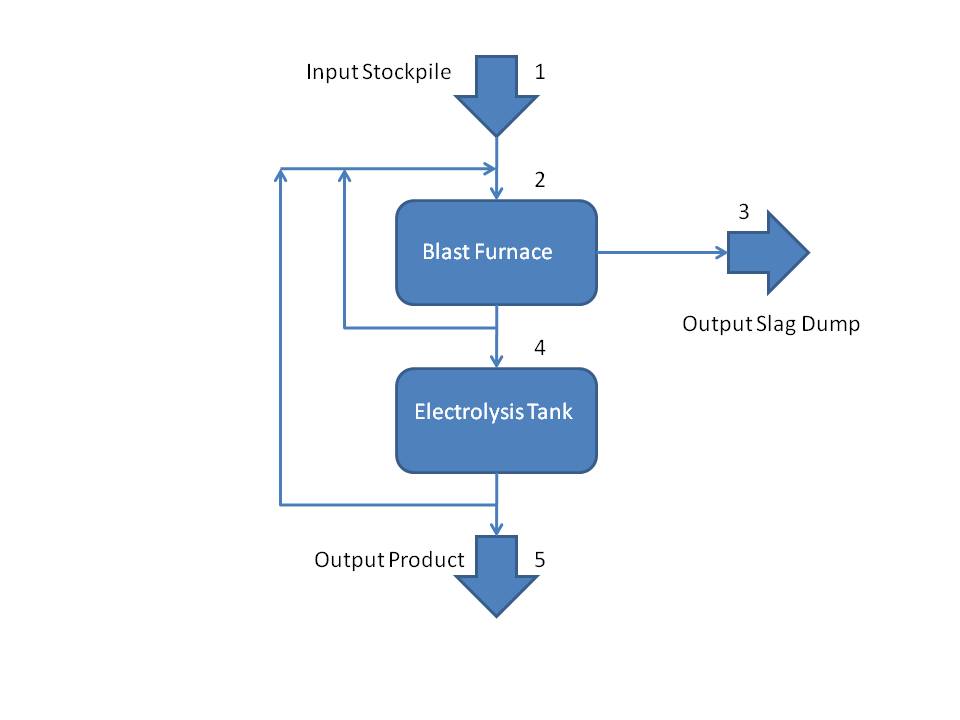

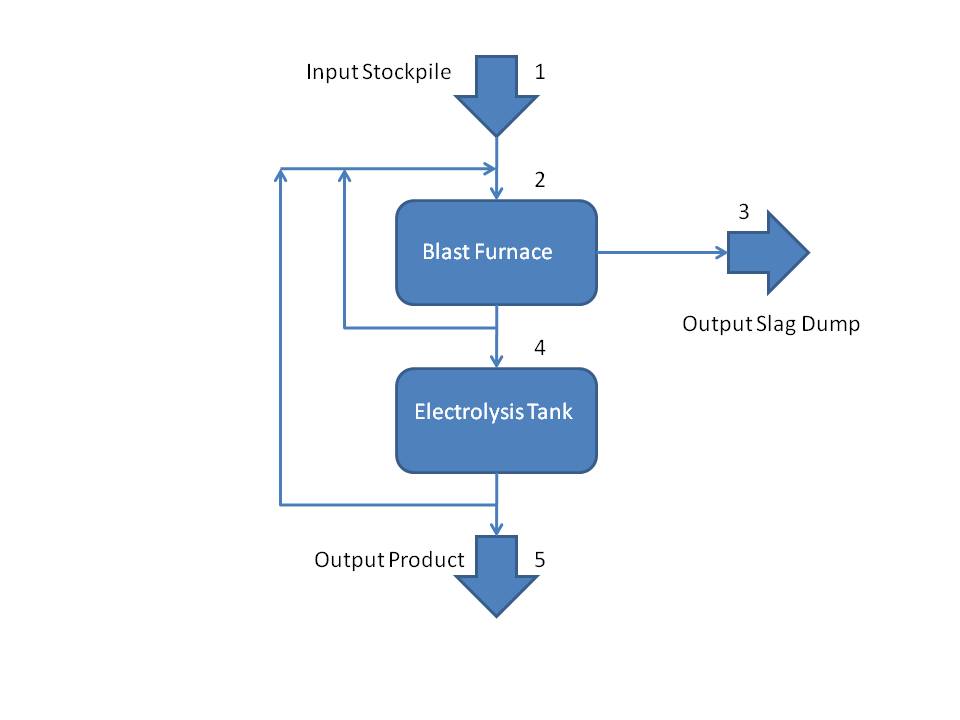

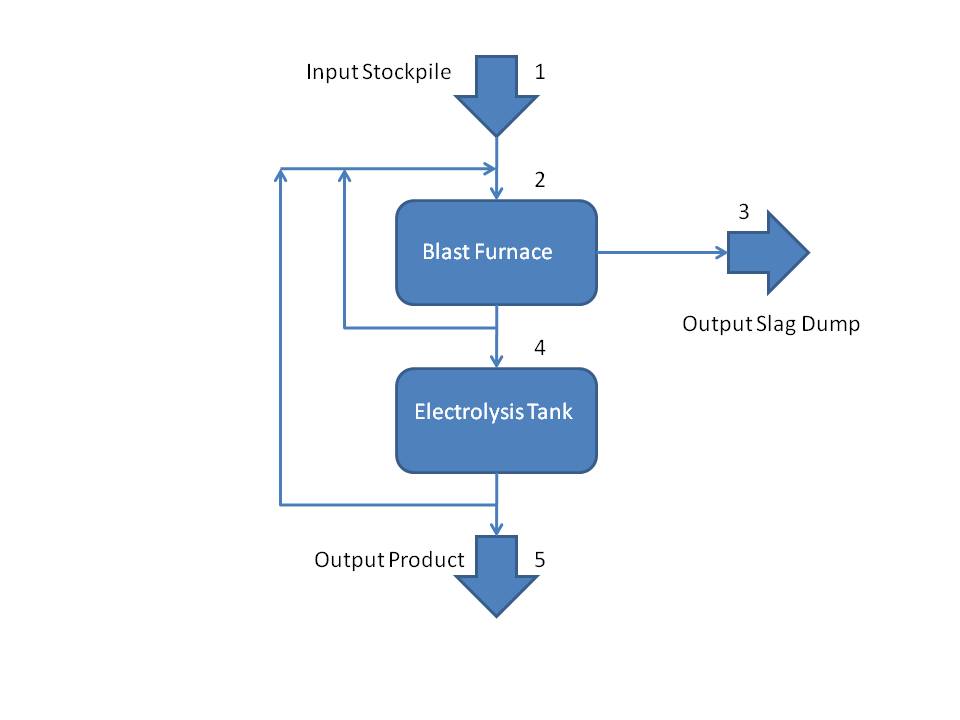

Background

This material is based on my experience as an undergraduate student

intern during the summer of 1975, doing computer programming to support

the engineers managing a copper refinery in northern Canada. I have

forgotten plenty of details, and simplified many others to make the

example easier to understand. Please don't

try to construct a smelter

based on these instructions! For the purposes of this example,

let's assume that refining copper ore into finished copper bars

requires two

processing steps, as shown in the following flow diagram.

The smelting process begins by loading some raw materials (copper ore

mixed with other inputs, such

as silica and coal) into a blast

furnace. Then lots of heast is applied until the mixture melts

and then separates into several

layers -- just like oil and water in a bottle of salad dressing, or the

fat and meat juices you collect from the bottom of the roasting pan

when making gravy. In this case, the top layer is impurities suspended

in molten silica, called slag,

which

cools into a solid material that looks like lava and is discarded

as waste. The bottom layer is rough copper, which is cast into slabs in

preparation for the second step. In between is an undifferentiated

mixture of ingredients with similar composition to the raw materials.

For the purpose of this example, let's assume that one "batch" of raw

materials at a time is processed by the blast furnace:

- The input is 100 tons total weight of raw materials

(approximately 10% copper and 90% other);

- The outputs, at the

end of an 8-hour shift, consist of:

- 40

tons of slag (0% copper, 100% other),

- 10 tons of rough copper

(75% copper, 25% other), and

- 50 tons of leftover material (5% copper,

95% other).

In addition, let's assume that the refining process carried out by the

furnace distributes the input copper among the three outputs

independently of all other material present inside the smelter. In

other words, looking only at the

processing of copper in our example, we see:

- The input is raw material that contains 10 tons of copper (100

tons * 10%)

- The outputs consist of:

- slag that contains 0 tons of copper (40 tons * 0%)

- rough copper that contains 7.5 tons of copper (10 tons * 75%)

- leftover material that contains 2.5 tons of copper (50 tons *

5%)

The second step of the smelting process

involves electro-deposition, which is similar charging a battery or

applying chrome plating to the exhaust pipes of a motorcycle. In this

case, the rough copper bars are immersed in a tank of electrolyte next

to some sheets of refined copper. When a DC voltage is applied between

the anode (rough copper) and cathode (refined copper), the copper atoms

move through the electrolyte as charged ions from anode to cathode,

until the anode is reduced to some left-over sludge (containing 10% copper, 90%

other) sitting on the bottom of the tank and the cathode has

grown into a large piece of refined

copper (containing 99% copper, 1% other).

Note, that

this information only tells us the relative amount

of copper in each output product, without giving you the total weight

of each output the way we had for the blast furnace. However, we can

find this missing incredient by solving a "mass

balance" equation for tracking the movement of copper. Assuming that no

material is created or destroyed inside the electolysis tank, our input

of 10 tons of raw

copper must generate a total of 10 tons of output, which is

split into z

and (10 - z)

tons,

respectively, of sludge

and refined copper.

Similarly,

the

total

amount

of

copper

(in

tons) entering and leaving the electrolysis tank is also equal, which

gives us the

following equation for the movement of copper:

10 * 0.75 = z * 0.1 +

(10 - z) * 0.99

This equation can be easily solved algebraically to give

z = 2.4 / 0.89 = 2.697

(Remember that the above lines are equations, not Matlab

commands, and the first line in particular will generate a Matlab

error, rather than doing what you wanted!)

Therefore, once we have found z, we can

represent the processing of copper at the electrolysis tank as follows:

- Input is rough copper that contains 7.5 tons of copper (10 tons *

0.75)

- Outputs consist of:

- sludge that contains 0.27 tons of copper (z tons of sludge

* 10%)

- refined copper that contains 7.23 tons of copper ((10 - z) tons of

refined copper *

99%)

In other words, the processing in the

electrolysis step distributes the input copper so that

(0.27 tons) / (7.5 tons) = 3.6%

is caught in the sludge, and the remaining

(7.23 tons) / (7.5 tons) = 96.4%

leaves the smelter in the form of its primary product: refined

copper bars.

It is also very important to not to forget about the

sludge, which is an "unwanted" output product generated by the

electrolysis tank. Since

the sludge the same concentration of copper (10%) as the original raw

materials entering the smelter, the sludge must be returned to the

blast furnace for further processing, rather

than simply thrown away.

Modeling the Smelter with Matlab

After a few preliminary calculations (i.e., solving for z), we have

converted the operation of the smelter into a series of simple

formulas, to say how the amount of copper (say) in each input/output

stream or processing step depends on the others. Thus, we could easily

write down a series of Matlab assignment statements to show how these

values change from one shift to the next. For example, suppose the

smelter is initially idle after a long vacation, and the first shift

shows up for work and starts to bring the smelter back online. Since

both the blast furnance and electrolysis tank are empty, the only crew

members at the input stockpile can do any real work, namely moving 10

tons of raw materials to the entrance of the blast furnace. Thus, a

"snapshot" of the smelter taken during the first shift can be

summarized by the following Matlab statement:

% first shift

input_copper = 10;

%

prepare

first

batch

of

raw

material

Similarly a smelter "snapshot" during the second shift looks like this.

The blast furnace crew has loaded the

input copper into the furnace and is now heating it. The

stockpile crew is moving another 10 tons of raw materials to the

entrance

of the blast furnace. All other crew members are still idle, so the new

"state" of the smelter looks like this:

% second shift

blast_furnace =

input_copper;

%

load

blast

furnace

input_copper

= 10;

%

prepare

another batch of raw

material

As the process continues, we get the follow sequence of Matlab

statements:

% third shift

slag =

blast_furnace * 0.0; % empty the blast furnace

raw_copper =

blast_furnace * 0.75;

leftovers = blast

furnace * 0.25;

blast_furnace =

leftovers + input_copper; % reload the blast furnace

input_copper =

10; % prepare another back of raw material

tank = raw_copper;

%

load

the

electrolysis

tank

slag_dump = slag;

%

disposal

crew

takes

slag

to dump

slag

=

0;

% fourth shift

slag =

blast_furnace * 0.0; % empty the blast furnace

raw_copper =

blast_furnace * 0.75;

leftovers = blast

furnace * 0.25;

sludge =

raw_copper * 0.036; % empty the electrolysis

tank

refined_copper =

tank * 0.964;

tank = raw_copper;

%

reload

the

electrolysis

tank

blast_furnace =

leftovers + input_copper + sludge; % reload the blast furnace

input_copper =

10; % prepare another back of raw material

output_product =

refined_copper;

% shipping crew sends final product to market

refined_copper

=

0

slag_dump = slag;

%

disposal

crew

takes

slag

to dump

slag

= 0;

% fifth shift ... Looks exactly the same as the fourth shift

Simplifying the Model by Introducing Matlab Matrix/Vector Notation.

Vector notation allows us to combine the results of one processing

"step" at the blast furnace, i.e.,

slag = blast_furnace *

0.0; % empty the blast furnace

raw_copper =

blast_furnace * 0.75;

leftovers = blast

furnace * 0.25;

into a single Matlab command:

blast_out

=

blast_furnace

*

[0.0

0.75

0.25]

blast_out

=

0 7.5000 2.5000

(where I have shown the answer produced by Matlab in red to

separate it from the commands I've been typing). The only

"inconvenience" is that I must recognize each output product by its

position in the vector, rather than a "nice" individually-chosen

variable. Don't worry, things will make more sense in a moment!

Notice that all the objects in the smelter diagram has been numbered

from 1 to 5. Therefore, let's begin by using those numbers to identify

each smelter object by its position in a 5-element, as shown in the

following table:

Old Name:

|

input_copper

|

blast_furnace

|

slag_dump

|

tank

|

output_product

|

New Name:

|

smelter(1)

|

smelter(2)

|

smelter(3)

|

smelter(4)

|

smelter(5)

|

For example, the current state of the smelter might look like this

after running for a few shifts

smelter

smelter =

10.0000

13.3950

0 9.3750 7.2300

Furthermore, notice that each of the "streams" of material (raw input,

slag, etc) has a comes from a single "producer" and goes to a single

"consumer". Thus, we can identify each "stream" produced by an object

by the number assigned to its consumer. In other words, even though the

blast furnace produces only three outputs, we should call them blast_out(1)

through blast_out(5)

so we know where they are going. In this case, our previous

Matlab command would be rewritten like this:

blast_out

=

smelter(2)

*

[0.0

0.25

0.0 0.75 0.0]

blast_out =

0 2.5000 0 7.5000 0

Similarly, we would represent the result of one processing step at the

electrolysis tank as:

tank_out

=

smelter(4)

*

[0.0

0.036

0.0 0.0 0.964]

tank_out =

0 0.2700 0 0 7.2300

For the remaining locations in the smelter, the result of one

processing step is very easy. Everything at the input stockpile is

loaded into the blast furnce, like this:

stockpile_out

=

smelter(1)

*

[0.0 1.0

0.0 0.0 0.0]

stockpile_out

=

0 10.0000 0 0 0

(I know the workers will refill the stockpile with a new input material,

but right now I'm focussing my attention on the movment of existing

material within the smelter. We will return come back to the input in a

few minutes.) On

the other hand, everything at the slag dump and product shipping area

is permanently removed from the system. Since none of the material

currently at either smelter(3) and smelter(5) is still somewhere inside

the smelter one shift from now, we can represent the those parts of the

process as a multiplication by a vector of zeros.

Let us now stack up these

"processing vectors" for each smelter location to form a two

dimensional matrix with location 1 (input stockpile) forming row 1 and

the product shipping area forming row 5:

shift =

[0 1.0 0

0 0

0

0.25 0 0.75 0

0

0

0

0 0

0

0.036

0

0

0.964

0

0

0

0

0]

Notice that we can use the colon operator to select a specific row from

this matrix:

shift(4,:)

ans =

0

0.0360

0

0

0.9640

and thus we can rewrite the previous command for the electrolysis tank

as:

tank_out = smelter(4) *

shift(4,:)

tank_out

=

0 0.2700 0 0 7.2300

More generally, let us now repeat this "trick" to generate the outputs

from one processing step at each of the five objects in the smelter

model:

stockpile_out = smelter(1) *

shift(1,:); % notice the semicolons to suppress

output

blast = smelter(2) *

shift(2,:);

slag_out = smelter(3) *

shift(3,:);

tank_out = smelter(4) *

shift(4,:);

product_out

= smelter(5) *

shift(5,:);

Clearly, we can find the input to some "target" object at the next

processing step, by summing all outputs generated in the current

processing step that are sent directly to the "target" object. For

example, if object 2 (the blast furnace) is our "target" object, then

its input for the next shift must be:

stockpile_out(2) +

blast(2) + slag_out(2) + tank_out(2) + product_out(2)

Fortunately, we can use matrix operations to avoid having to deal with

all these tedious details. More specifically, let's now go back and

look at the outputs generated by the "trick" a few lines ago. (Notice

how I used the disp(

) command, so we see only the values of each variable, which is

a 5-element row vector, without showing any of the variable

names.)

disp(stockpile_out),

disp(blast),

disp(slag_out),

disp(tank_out),

disp(product_out)

0

10 0

0 0

0

3.3487

0

10.0463

0

0

0

0

0 0

0

0.3375

0

0 9.0375

0

0

0

0 0

To convert this two-dimensional table of values into the contents of

the kth

object in the smelter model at the next processing step, we must add

together every element in the kth column.

Using vector notation, we can do this simultaneously for every object

in a single Matlab expression, like this:

stockpile_out +

blast + slag_out + tank_out + product_out

ans =

10.0000

13.6862 0

10.0463 9.0375

So here is the bottom line for all of the discussion above. The way we

got from the 5-element row vector smelter

and 5x5 matrix shift was to

multiply the rows of shift by the

corresponding element from the vector smelter to form

a 5x5 table of results, and then "flattening" the table by adding the

elements in each column. This entire

series of steps is exactly what happens automatically when we apply

ordinary matrix multiplication to vector smelter and array shift.

Thus, all we really needed to do

to model the operation of the smelter is the following. To move forward

in time by one shift, we must redistribute the contents of smelter (i.e.,

the material currently in the system) by multiplication by the shift matrix,

then adding the the vector input

(representing the new material added from the stockpile every shift),

like this:

>> input=[10 0 0

0 0], smelter=input

input =

10 0

0 0 0

smelter =

10 0

0 0 0

>> smelter=smelter*shift+input

smelter =

10 10

0 0 0

>> smelter=smelter*shift+input

smelter =

10.0000

12.5000

0

7.5000 0

>> smelter=smelter*shift+input

smelter =

10.0000

13.3950

0 9.3750 7.2300

>> smelter=smelter*shift+input

smelter =

10.0000

13.6862 0

10.0463 9.0375

>> smelter=smelter*shift+input

smelter =

10.0000

13.7832 0

10.2647 9.6846

>>

We can keep going forward like this, one shift at a time, way for as

long as we like. However, the obvious question is what happens a very

long time in the future? Is there a long-term

"steady-state" distribution of material in the smelter over a shift,

and if so, how do we find it?

The answer to this question is very simple in Matlab, if you apply what

you know about how to find the sum of a (scalar) geometric

series. In other words, suppose I make n new friends every day, but

at the same time loose a fraction (1-p) of my existing friends because I

don't pay enough attention to them. How many total friends will I have

in the distant future? Clearly I will have n from today, n*p from

yesterday, n*p^2

from two days ago, etc, giving me a total of n/(1-p).

Similarly, the contents of the smelter will include input from the

current shift, input*shift

remaining from the previous shift, (input*shift)*shift

remaining from two shifts ago, etc., which is just another geometric

series, which can be solved in the same way to give:

>> input/(eye(5)-shift)

ans =

10.0000

13.8313 0

10.3734 10.0000

>>